Description

| Type of Filter | Dia. mm | Material | Retention Micron Rating Absolute |

Length inches | End Fitting Options | Gasket Material | Connection reinforcement |

| CPL Pleated |

D = 69 | S = SS | 001 003 005 010 |

10” 20” 30” 40” |

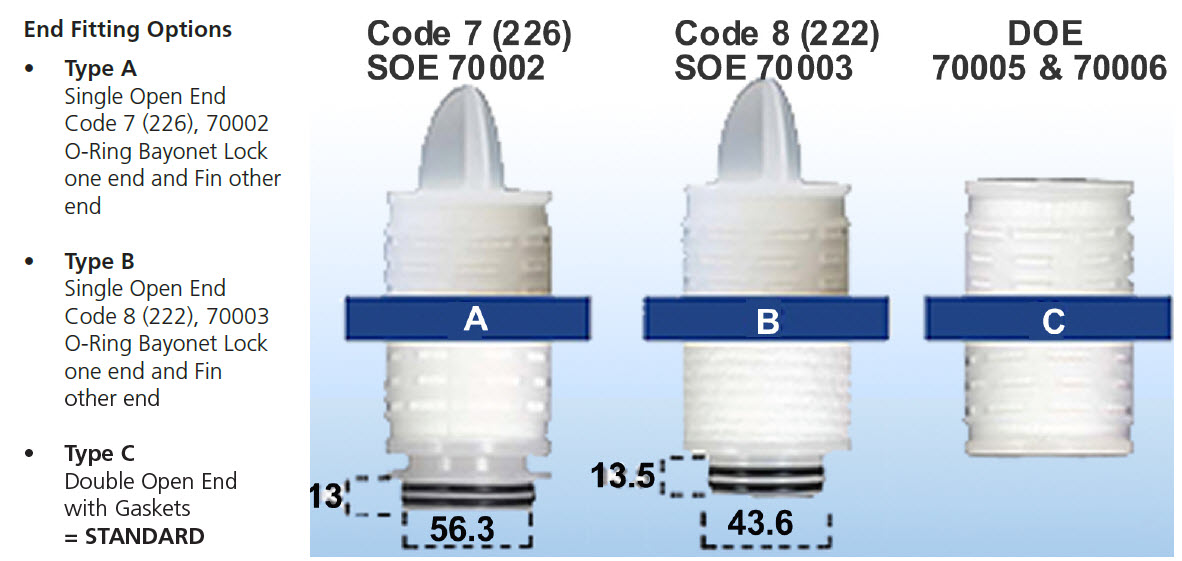

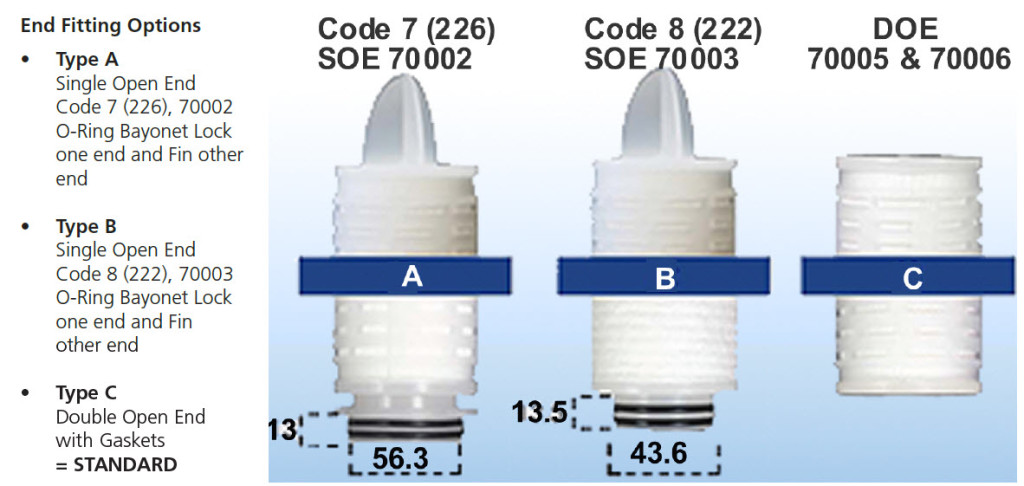

A B C |

S = Silicone E = EPDM V = Viton |

S = 304 SS |

| Max. operating temperature 200° C – Max. differential pressure 6 bar at 20° C | |||||||

| Order Example: Cartridge 69 mm diameter, 0.1 Micron, 10” long, with Single open End, Viton: CPLD-S010-10AV |

|||||||

| Type of Filter | Dia. mm | Material | Retention Micron Rating Absolute |

Length inches | End Fitting Options | Gasket Material | Connection reinforcement |

| CSI Sintered |

D = 69 | S = SS | 001 003 005 010 |

10” 20” |

A B C |

S = Silicone E = EPDM V = Viton |

S = 304 SS |

| Max. operating temperature 200° C – Max. differential pressure 6 bar at 20° C | |||||||

| Order Example: Cartridge 69 mm diameter, 0.1 Micron, 10” long, with Single open End, Viton: CSID-S010-10AV |

|||||||