PVBM Multi Bag Steel Pressure Vessels Side Entry – Versatile universal design

You are here: Home › Products › PVBM Multi Bag Steel Pressure Vessels Side Entry – Versatile universal design

Stream Tex offers a variety of pressure vessel solutions for your industry in Australia and New Zealand.

Features

• Cost-effective solution

• Perfect bag to housing sealing, no by-pass

• Able to handle very high flow rate and high dirt holding capacity

• ASME Design

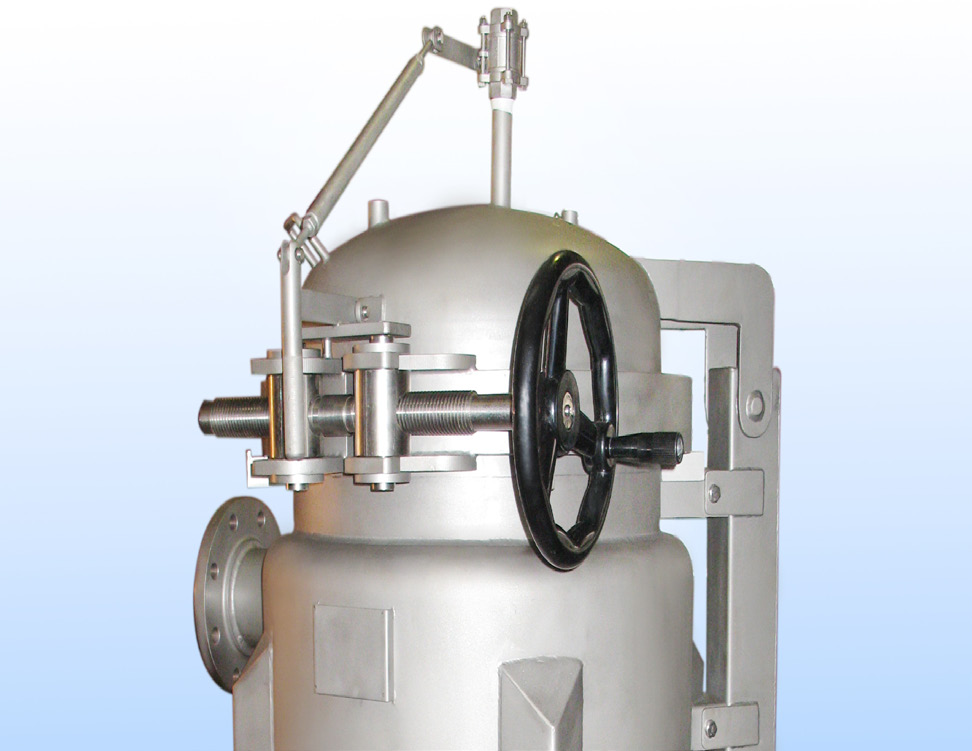

• Rugged, reliable

PVBM Multi Bag Steel Pressure Vessels Side Entry – Versatile universal design

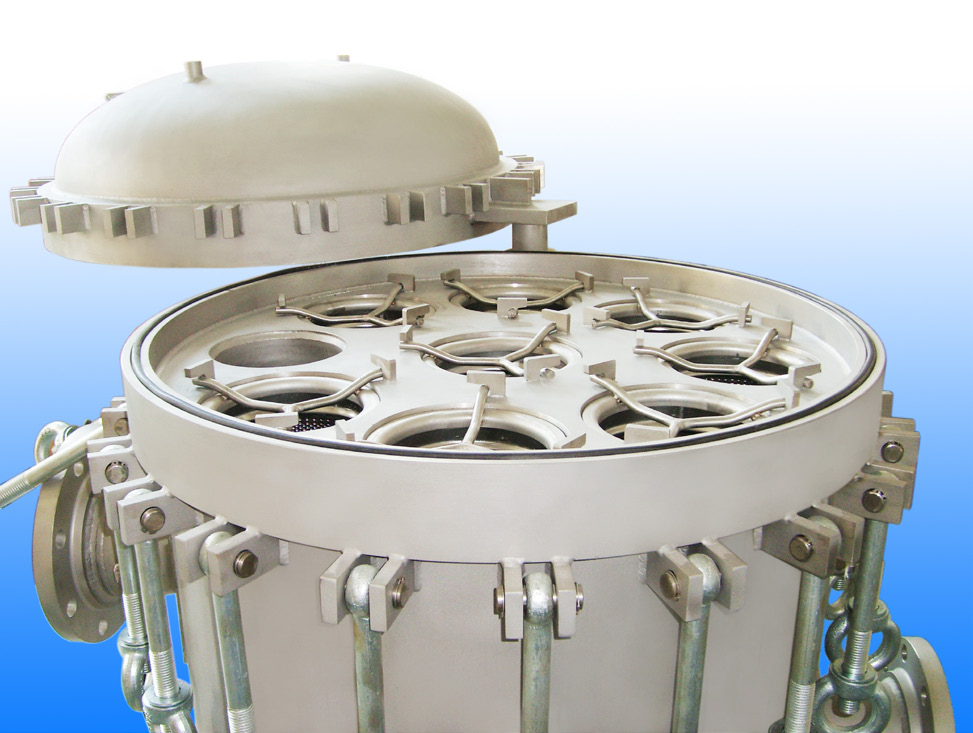

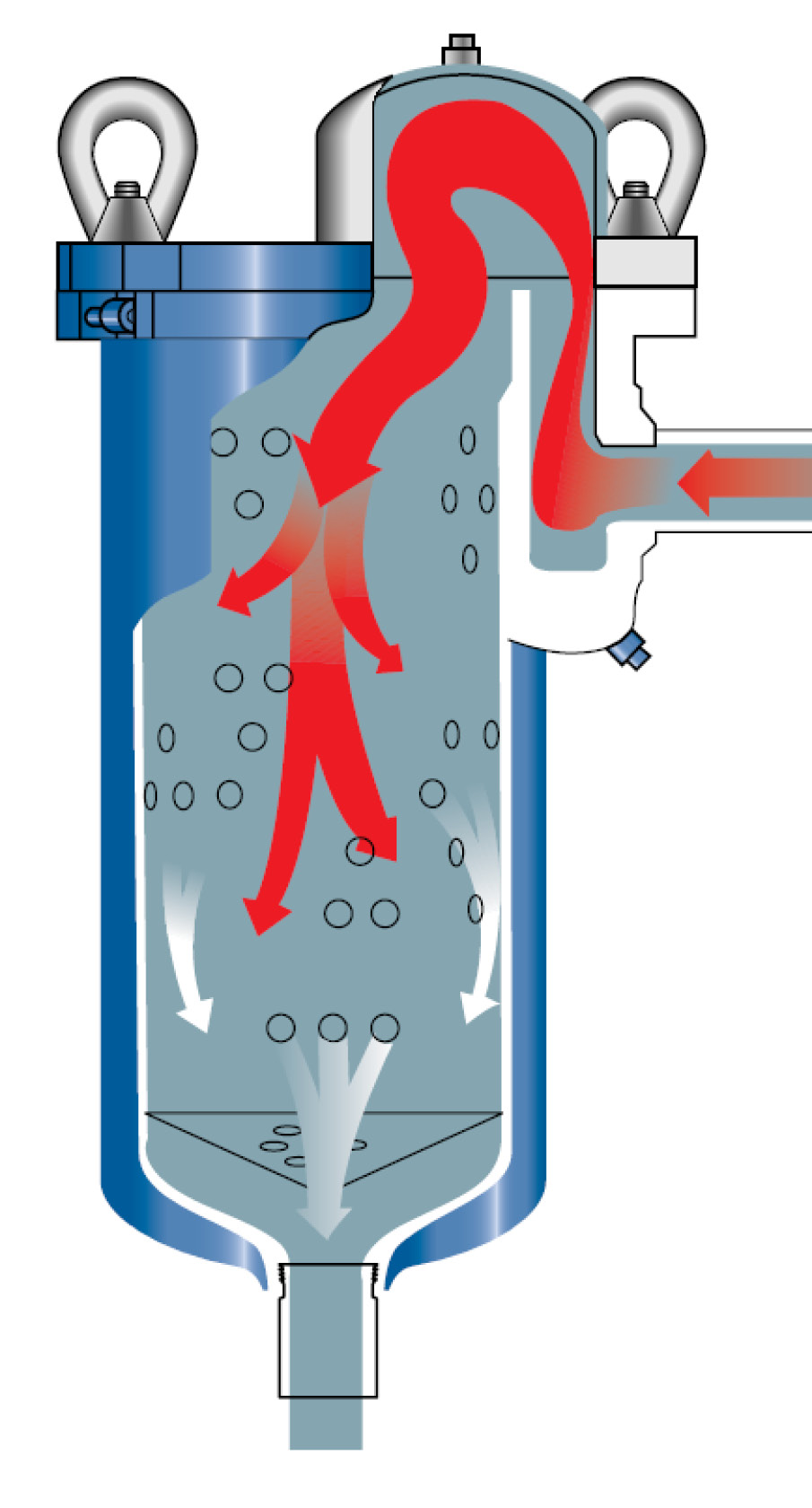

The StreamTex top inlet bag filter is designed to give perfect 360 degree sealing of a plastic collar fully welded type filter bag. The bag sits inside the filter clamped by the combined lid with inlet to ensure absolute no bypass.

This provides exceptional performance in the most challenging liquid filtration processes and the best seal design suitable for critical filtration demands in food and beverage, pharma and biopharma industries.

Vessel sizing / System configuration

*Maximum flow rate is based on aqueous flow at ΔP=1.0psi clean through filter only without bag installed.

Achieved flow rate is dependant on type of fluid being filtered, fluid viscosity and temperature, micron rating and type of filter bag. Please consult one of our product specialists when sizing these vessels.

If you would like to download the drawing of the vessel, please click on PV-BM12.

Contact Us to order steel pressure vessels in Australia and New Zealand.