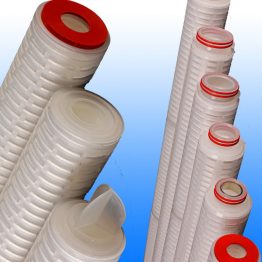

A pleated polypropylene filter cartridge is an essential component in many industrial applications such as food and beverage, pharmaceutical, chemical, water treatment as well as other equipment such as vessels. It is employed in methods of purification and filtration in different step of applications. This method is known as membrane filtration.

Before deciding which pleated polypropylene filter cartridge to use, it is important to understand what membrane filtration is in the first place. In this guide, we take a closer look at the technology and its history. We will also examine why it has proven so revolutionary across different industries and processes.

Why Membrane Filtration Technology is Important

There are many everyday applications that use membrane filtration. The technology is routinely used in water purification and treatment of even wastewater. It is also a common procedure in certain food and beverage industry procedures. The medical and pharmaceutical industry also employ membrane filtration technology.

History of Membrane Filtration

The genesis of the technology currently employed as membrane filtration can be traced as far back as the early 18th century. This is the earliest that the word ‘osmosis’ came into common usage. It was used to describe the concept of water permeating through a diaphragm. A diaphragm is essentially a natural membrane.

Over the centuries this rudimentary form of osmosis has evolved to bring about more effective, efficient and reliable technologies. These include gas filtration, electrodialysis, and membrane distillation. While based on the same natural concept as osmosis, these technologies have proved far more suited to certain processes and industries. Their adoption by businesses and institutions has sparked revolutionary advances in the development of industrial products as well as the innovation of newer applications and processes.

Examples of how improved membrane filtration technology has helped advance humanity and modernity abound everywhere. Thanks to these advances, we have better methods of making concentrates for fruit juices for instance. We can also remove impurities and contaminants from wastewater and tap water more effectively. The technology is also essential in the process of harvesting cells for use in the production of antibiotics.

Why Membrane Filtration is Better than Conventional Filtration?

There are several compelling arguments about why membrane filtration is a great technology. Compared to conventional methods of filtration, the technology has proved versatile and reliable. This is true whether you are talking of sedimentation, coagulation, floatation of dissolved air or even sand filtration.

The most obvious advantage of membrane filtration compared to these alternatives is about quality. The products made using membrane filtration are of superior quality and purity. The process also delivers the separation of elements with greater reliability.

When you use membrane filtration instead of traditional filtration techniques, you are assured of higher separation capacity. The risk factor for impurities slipping through and ruining the end product is also greatly reduced. What’s more, equipment which uses membrane filtration takes a much smaller space, a great competitive advantage for industries where production floor footprint is crucial. Moreover, when using membrane filtration, you will need far lower amounts of chemical reagents.

The Outlook for Membrane Filtration Technology and Applications

Into the 2020s, filter membrane technology is predicted to become even more ubiquitous. Over the last few years of the 2010s, the industry was growing at an average rate of over 7% in the United States alone. With freshwater shortages predicted to become even more acute in the new decade, it is only natural that demand for membrane filtration will become even higher. Moreover, many authorities and regulators are implementing stricter requirements for food and beverage safety.